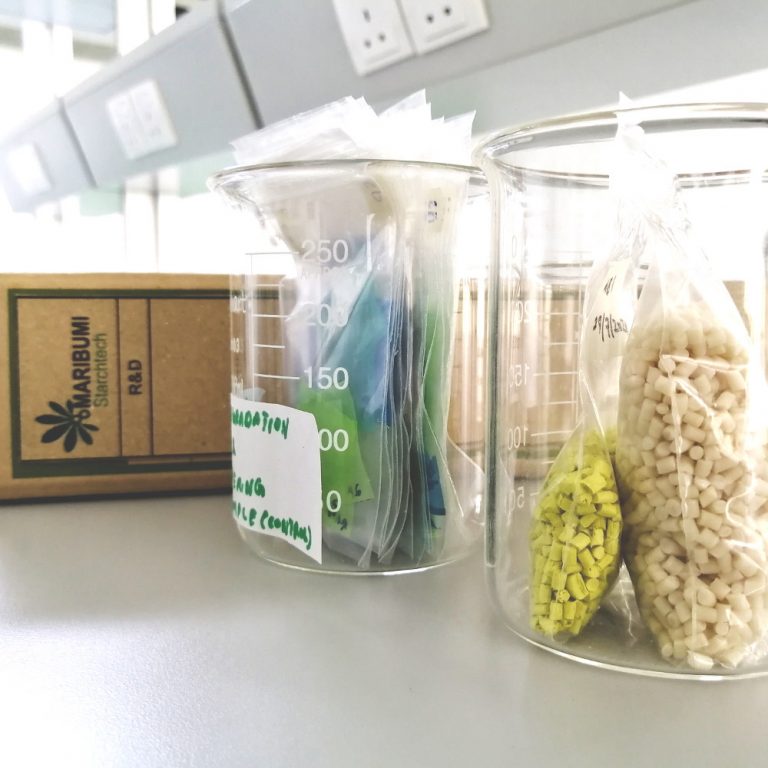

In our research and development centres, our team utilise advanced equipment to develop, analyse, and test our raw materials and finished compostable products during product development, quality control, and benchmarking.

The physical and mechanical testing of bio-compostable products is a crucial part during our product development and production process. Several mechanical tests have been performed on our bio-compostable products to ensure our products adhere to relevant ASTM International Standard which tested by SIRIM QAS International Sdn Bhd.

TEST METHOD | DESCRIPTION | PURPOSE | RESULT |

|---|---|---|---|

ASTM D882 | Tensile Strength

• Machine Direction

• Transverse Direction | To measure the elasticity of products. | 16.2 MPa ± 0.7 MPa

14.2 MPa ± 0.7 MPa

|

ASTM D1709 | Dart Drop Impact | To evaluate the impact strength or toughness of a plastic film. | 759 g |

ASTM E1252 | FTIR Analysis

Main functional group in the sample

FTIR Analysis

Common Plastic Polymers:

• PVC

• Phthalates

• Polyethylene (PE)

• Polypropylene (PP)

• Polystyrene (PS)

• Bisphenol A (BPA)

| To observe the chemical properties of products. | Ester group

The common conventional plastic polymers are not detected in our products. |

BS EN 1122

SW 846 7473

APHA 4110B

| Heavy Metals Analysis

(Arsenic, chromium, copper, lead, mercury, molybdenum, nickel, selenium, zinc, fluorine)

| To measure the concentration of heavy metals in products. | All heavy metals below the maximumconcentration according to SIRIM ECO 001:2018 |

There are two types of bio-resin material usually used for manufacture products: biodegradable and compostable.

Bio-resin is made from organic and renewable materials which is environmentally friendly and toxologically safe resin. The most common sources are plant-based, which then process to become resin. Maribumi Starchtech’s bio-resin is both certified as 100% biodegradable and compostable. These resins are used during our production process to become our finished products, where we regards them as bio-compostable products due to their credentials.

Similarly, they are wholly or partly derived from materials of biological origin (living organisms) that can help reduce carbon dioxide (CO2) and lower dependence on petrochemicals such as oil and natural gases. Bio-based materials, bio-resins are receiving much attention as an alternative due to the fact that it has a positive effect on our carbon footprint and also incredibly environmental in its manufacturing process which can reduce the damage incurred by our CO2 emission whereby to substitue petroleum-derived synthethic products.

Our products are made of biodegradable and compostable resin (raw material), formulated with natural plant based that is certified biodegradable during composting in professionally managed composting facilities which certified by:

Note: Please contact our sales representative for further info on the certification

ASTM E1252- Standard Practice for General Techniques for Obtaining Infrared Spectra for Qualitative Analysis (Tested by Sirim QAS International Sdn. Bhd.).

The Result

Main functional group in the sample is ester group and common plastic polymers such as PVC, Phthalates, Polyethylene (PE), Polypropylene (PP), Polystyrene (PS), Bisphenol A are not detected in our products.

Note: Please contact our sales representative for further testing report

Our bio-compostable is certified under the SIRIM Eco-Labelling Scheme (Lic. No.: EL000197) and under Malaysian Green Technology & Climate Change Centre (MGTC) with MyHIJAU mark (MyHP00125/22).

The main differences are biodegradable products could be referring to any material which breaks down and degrades in the environment, whereas compostable products are only organic elements that decompose in the environment. Besides, compostable products that break down in compostable environments will only leave behind beneficial residual products like fertilizers and others which can improve the soil health. On the contrary, biodegradable plastic depends on the element of fabrication which means that some of them can leave micro toxic waste residue behind.

No. Conventional plastics are fossil-based and non-compostable or biodegradable.

Conventional plastic does not biodegrade or decompose due to their profound stability. Conventional petroleum-based plastics take so much time to break down that is effectively around forever. These plastics are made with petrochemicals such as oil and natural gases, which are non-renewable resources and only available in limited supplies. Their chemical bonds are too strong and their molecules will not break down by natural processes. This is why many plastic materials can last for many years. If they are not disposed properly, it can cause pollution, block drains and harm animals.

*Biodegradation can take any amount of time to occur. Composting is the natural decomposition of organic waste by microorganisms within a specified time period. Biodegradation is the natural decomposition of organic waste by microorganisms. It is the process in which the molecular structure of a material breaks down through an enzymatic or metabolic process.

We recommend you store the compostable product in normal room temperature range, together with silica gel provided in packaging box and avoid from direct sunlight. Our products can last up to 2 years if stored properly and correctly.

High humidity, too high & too low surrounding temperature, too much UV light and sunlight exposure, as well as presence of microorganisms.

There are many ways to reuse these useful little packets in our everyday life. They can help to keep many everyday items fresh and free from unwanted damp and moisture by including a few packets in bags and boxes such as in shoe and clothing storage.

Yes. Please contact our sales representative for further information.

Depends. We can go below 10,000pcs. However, that will depend on the amount that requested by customers. You may contact our sales representative for further information. As for the products on our website, they are ready stock so you can select according to the amount that you are able to select.

For bulk orders, price is different. Please contact our sales representative to request quotation.

Yes, we do. In fact, we are pleased to work in partnership with any organisation and looking into having collaboration with community whom are committed to eco-innovation and to extend our supports to solve the plastic pollution.

Kindly drop us an email at sales@maribumistarchtech.com or enquiry@maribumistarchtech.com